In Septeber 2025, Kingfisher (Shanghai) Marine Services Co., Ltd. successfully completed three core tasks for the vessel M.V. AKIJ NOBLE: propeller trimming, propeller repair, and FINCAP installation. The project strictly adhered to class-approved drawings (e.g., 074-PRO 0601-A PROPELLER TRAILING EDGE MODIFICATION-BV) and international standards (e.g., ISO484/1-2015-E), ensuring compliance with marine safety and performance requirements. All tasks were verified by the ship’s master and passed quality inspections, effectively restoring propeller efficiency, enhancing operational safety, and optimizing vessel performance.

Project Scope & Core Tasks

The project covered three interrelated tasks, each with standardized procedures and strict quality control measures:

1. Propeller Trimming

The trimming focused on optimizing the propeller’s trailing edge to improve hydrodynamic performance, with a 4-step workflow:

l Preparation: Collaborated with the shipyard to dismantle the propeller, move it to a 9m×9m covered working area (with 220V power supply), and deploy a team of 1 engineer + 2 workers equipped with electric cutting machines, pitch gauges, and custom templates.

l Execution:

1) Created blade cutting and trailing edge tip templates based on class-approved drawings.

2) Marked smooth transition cutting lines on Blades A-D using radius measurements.

3) Cut the trailing edge with a cutting machine and ground it to the specified profile, including anti-singing treatment on the suction side.

l Inspection:

1) Visual and template-based profile checks (0.7R, 0.8R, 0.9R, 0.95R, 0.975R for each blade) to ensure smooth transitions.

2) Penetrant Testing (PT) on cutting areas: no surface cracks detected.

3) Static balance check: Collected and weighed cut/ground material from each blade (weights: A=1.445kg, B=1.58kg, C=1.67kg, D=1.68kg). The maximum mass deviation (0.235kg) was far below the allowable 2.35kg (per the vessel’s PROPELLER FAT REPORT), confirming qualified balance.

l Delivery: Submitted the final trimming report to the shipowner within 2 working days of completion.

|  |

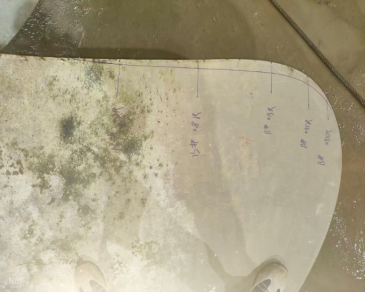

| Site preparation and inspection before propeller trimming | |

|  |

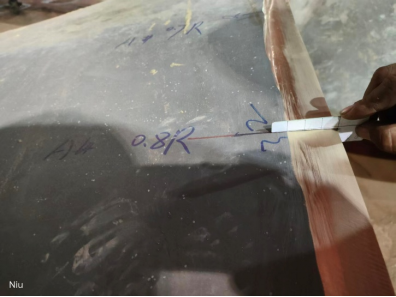

| Use the prepared template to mark the radius line and cutting line | |

|  |

| Trailing edge cutting and Anti-singing polishing | |

|  |

| Grinding to specified profile | |

|  |

| Profile check | |

|  |

| Static balance check:the weights of cut part and grinding part of Blade | |

|  |

| PT check the trimming area, no defects were found | |

2. Propeller Repair

The repair addressed edge nicks on the leading edges of Blades A-D, following a rigorous 8-step process to restore structural integrity:

l Preparatory Review: Prepared Welding Procedure Specification (WPS), welder certificates, and welding consumables for BV (Bureau Veritas) review.

l Defect Detection: Conducted PT on damaged areas to identify nick boundaries and ensure no hidden cracks.

l Grinding & Welding:

1) Ground damaged areas to remove defects and create a clean welding surface.

2) Welded per WPS: Preheat temperature ≥150°C, shielding gas (99.99% Ar), interpass temperature ≤250°C.

l Post-Weld Treatment:

1) Heat treatment: Heating rate 80°C/h, cooling rate 50°C/h to relieve internal stress.

2) Polishing: Shaped the repaired area to match the original propeller profile.

l Final Inspection: PT on all repaired areas confirmed no defects; the propeller met structural and performance requirements.

|  |

| Damaged areas status before repair | |

|  |

| PT check the damaged areas | Follow the WPS proceed with welding |

|  |

| Post-weld treatment by heating | Grinding and polishing after heat treatment |

|  |

| PT check for the repaired area, no defects were found | |

3. FINCAP Installation

Kingfisher supplied a custom-designed FINCAP and installed it with precise alignment and torque control:

l Pre-Installation: Delivered the FINCAP onboard and verified its compatibility with the propeller.

l Installation Execution:

1) Aligned the FINCAP centerline with the propeller to ensure concentricity.

2) Tightened bolts and nuts to a torque of 600NM, then secured bolts with wires to prevent loosening.

3) Applied cement to seal gaps and enhance structural stability.

|  |

| KINGFISHER designed FINCAP delivered onboard | Installation in progress |

|  |

| FINCAP centerline mark aligned with propeller | Bolts & nuts tighten with the torque of 600NM |

|  |

| The torque is 600NM | Bolts been secured with wires |

Copyright © 2009-2011, 版权所有 © 您的网站名称 未经许可 严禁复制 沪ICP备XXXXXX号