Key Regulation

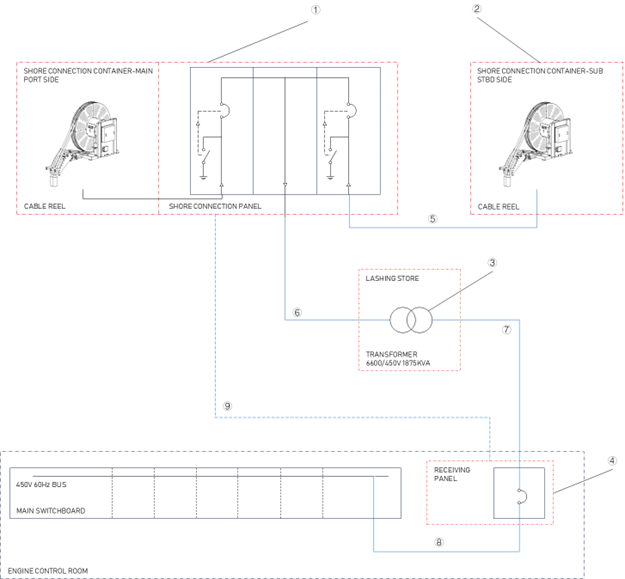

⑤ CONTAINER-MAIN TO CONTAINER-SUB

⑥ CONTAINER-MAIN TO TRANSFORMER

⑦ TRANSFORMER TO SHORE RECEVING PANEL

⑧ SHORE RECEVING PANEL

TO MAIN SWITCHBOARD

⑨ CONTAINER-MAIN

TO SHORE RECEVING PANEL

① SHORE CONNECTION CONTAINER-MAIN

(PORT SIDE)

- CABLE REEL

- SHORE CONNECTION PANEL

② SHORE CONNECTION CONTAINER-SUB

(STBD SIDE)

- CABLE REEL

③ TRANSFORMER (6600/440V)

(IN LASHING STORE)

④ SHORE RECEIVING SWITCHBOARD

(IN ENGINE CONTROL ROOM)

CABLES

Design & Engineering

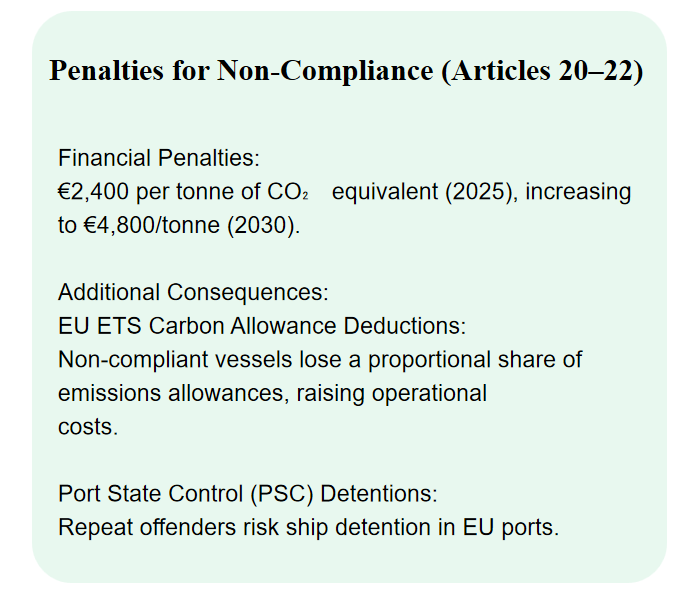

FuelEU Maritime Regulation (EU) 2023/1805(Enforced from January 1, 2025, with phased implementation) Critical Compliance Requirements (Article 4(1)):

Applicability:

Mandatory for container ships and passenger vessels calling at EU/EEA ports.

Required when berthed for >2 hours.

Obligations:

Use shore power (AMP) or zero-emission alternatives (e.g., hydrogen, batteries).

Minimum compliance: 50% of onboard energy demand from AMP by 2025, rising to 100% by 2030.

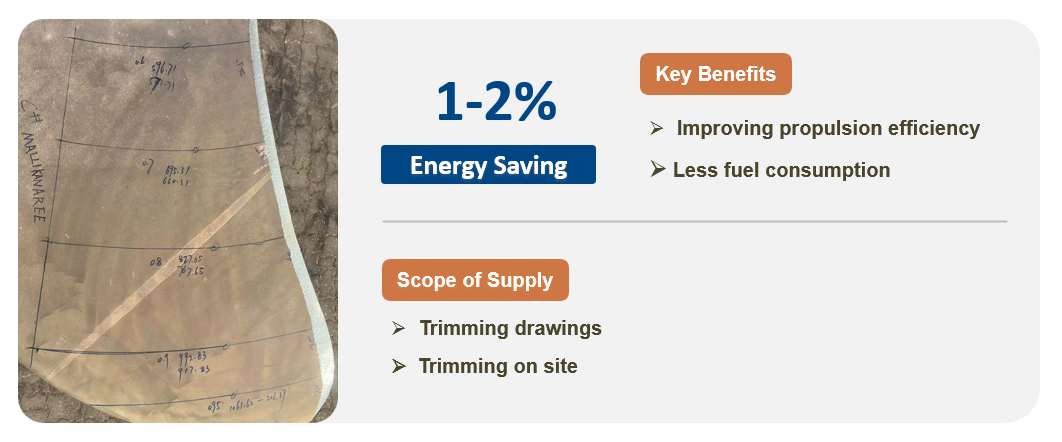

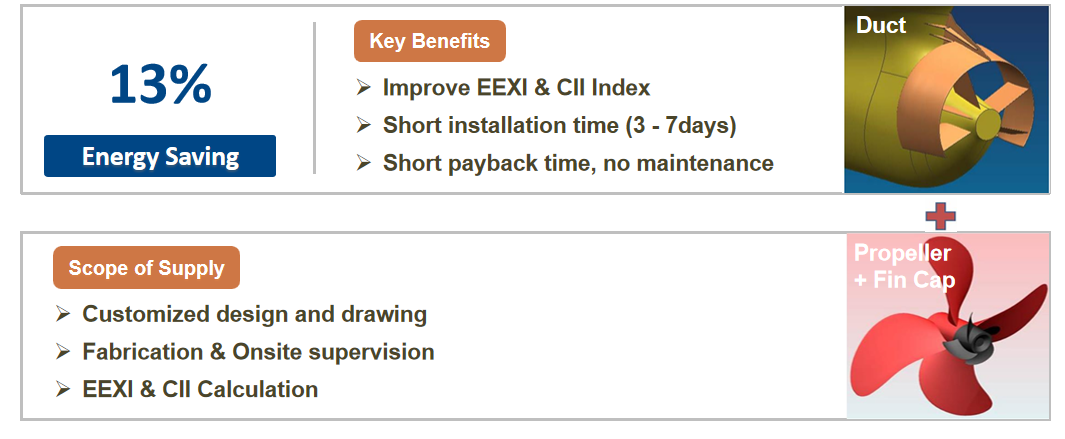

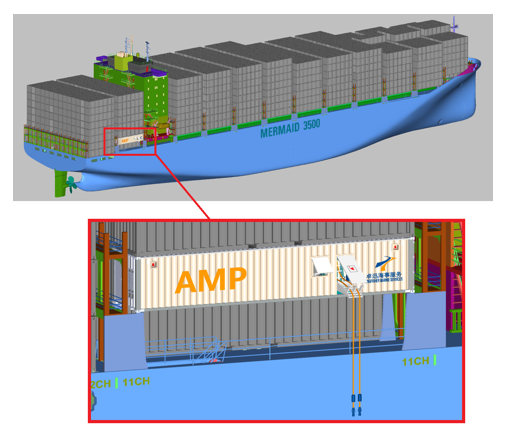

- AMP System Design Complete AMP container design

(structural, electrical, HVAC)

- Product certification

- Interface specification (power connection points, load calculation)

- AMP Container Supply

(cable reels, shore connection panel, transformer 6600/440v

shore receiving switchboard)

- Cables, connectors, control systems

- Transportation to shipyard

Equipment Supply & Logistics

EQUIPMENT

EXCELLENCE / CELERITY / DEDICATION / /RELIABILITY

GREEN SOLUTIONS

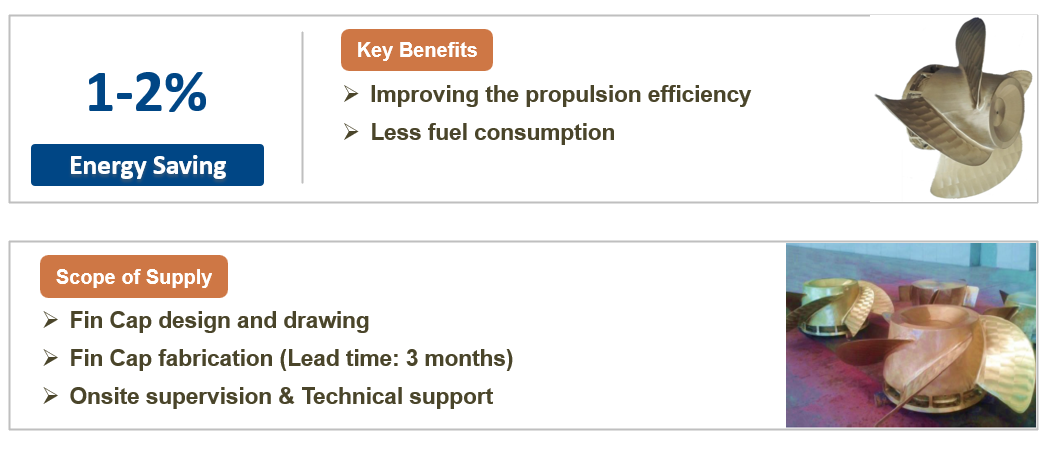

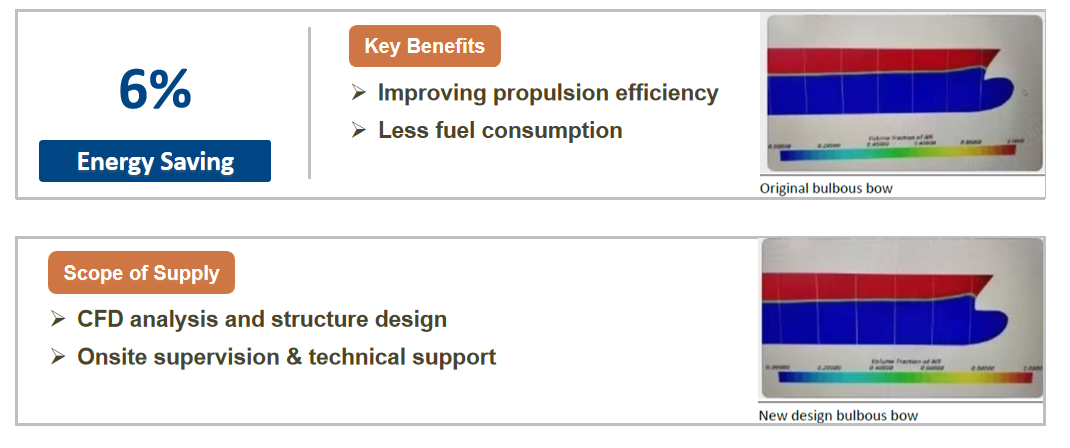

6.5%

ØLess fuel consumption

for 57K Bulk Carrier

Technical Support for Installation & Commissioning

- Service engineers attend on board for supervision

(two weeks)

- Guide AMP connection to ship’s electric system

- Manage functional tests

(shore power switchover, load balancing)

- Crew training for AMP system operation

After-Sales Services

- 24 months warranty

- Remote instruction and spares supply

Advantage of Kingfisher Solution

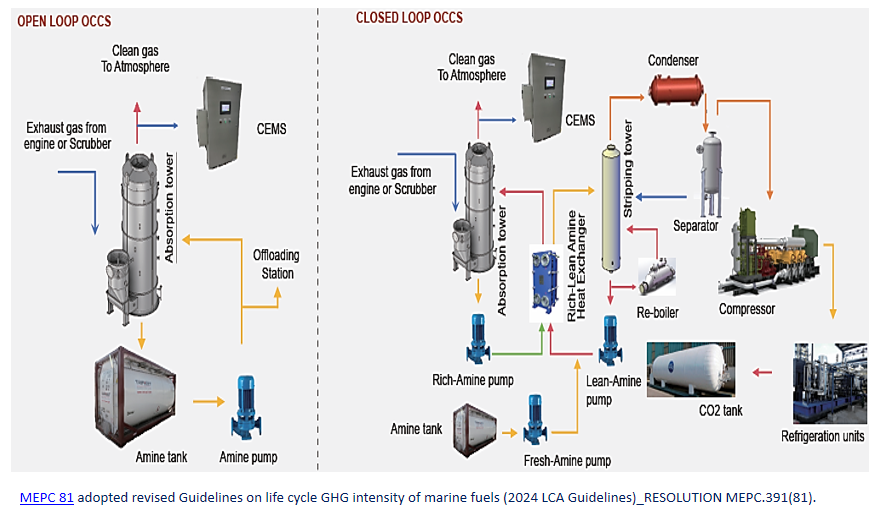

Applications on board

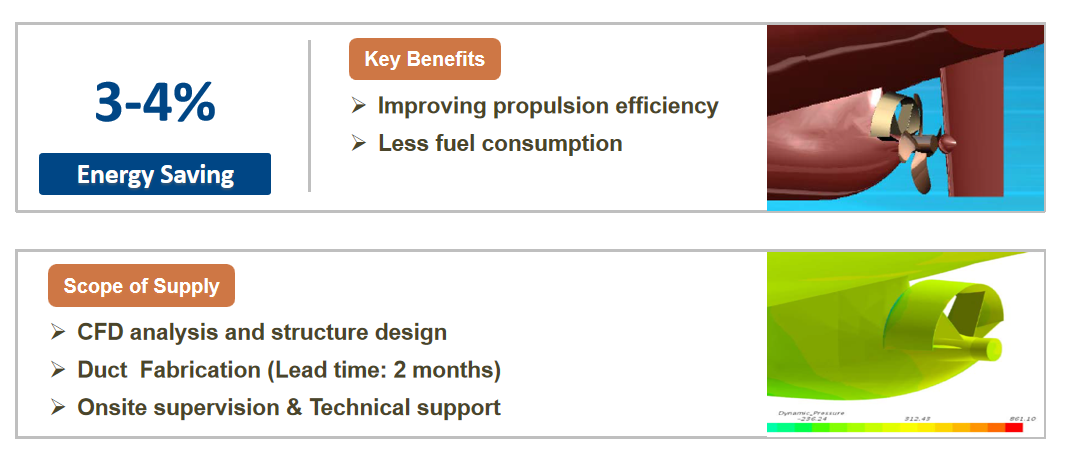

Exhaust Gas from EGCS

CO2 Captured Rate 20%-30%

Cooling & Absorption

Heat Exchanger

Amine circulation

Heating & Stripper

CO2 Compression & Storage Liquid CO2

Off load