In Oct. 2025, the propeller trimmings, repairs and FINCAP installations for two Supramax from a Bangladesh owner have been completed in COSCO Zhoushan Shipyard and COSCO Guangdong Shipyard.

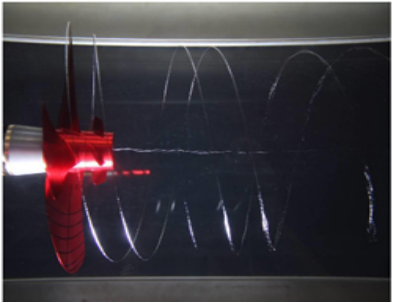

The ESD solutions complied with EEXI regulations, matched the vessels’ main engine systems and adhered to class-approved standards. The work aimed to boost fuel efficiency, optimize speed, cut carbon emissions and restore the propeller integrity.The combined implementation of propeller trimming and FINCAP installation achieved a 2.5% energy saving effect.

Kingfisher collaborated with COSCO Shipyard during dry-dock, offering end-to-end support: coordinating propeller dismantling, shore positioning, supplying tools, conducting PT to eliminate cracks, checking static balance (max deviation 0.12kg < permissible 8.63kg) and doing post-installation speed trials. FINCAP installation included precise alignment and bolt tightening to 225 NM (supervised with the shipyard). Speed trials confirmed both propellers met performance goals.

|  |

Weld missing part of trailing edge | Static balance chec |

|  |

Propeller Condition after trimming and repair | |

|  |

Fincap installation | |

|  |

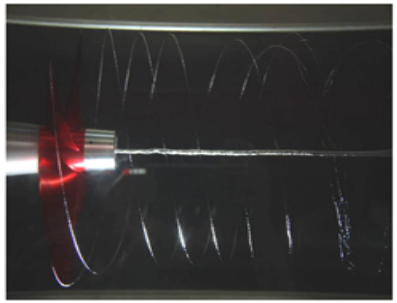

Wake field without Fincap | Wake field optimized with Fincap |

Copyright © 2009-2011, 版权所有 © 您的网站名称 未经许可 严禁复制 沪ICP备XXXXXX号